Automated Conveyor Cleaning ACC

DESCRIPTION & FUNCTION

Lagafors®

Automated Conveyor Cleaning, ACC, is developed for the cleaning of different types of conveyors. By using existing central units like Lagafors VPP 8090 and VCC, conveyors are cleaned at low cost. The system saves water, chemicals and time by optimizing the parameters: pressure, chemical solution and cleaning time. Each conveyor can be set to separate parameters. The ACC can be connected to other pump units within the technical specifications.

Lagafors ACC key components:

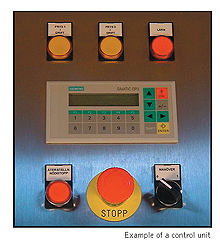

- Control unit with operator panel in stainless steel.

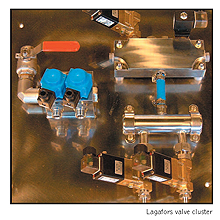

- Valve clusters for variable media at different conveyors.

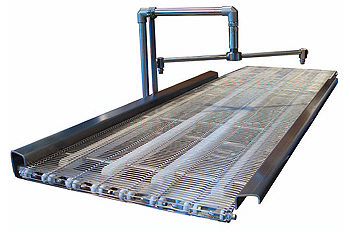

- Customized rotating nozzle clusters.

Features

- Rotating and fixed arms

- Immediate start function

- Individual cleaning cycles

Benefits

- Efficient cleaning of all moving parts

- Saves time

- Optimizing cleaning parameters

Facts

- Visible hygienic results

- Reduces cleaning costs

- Cost and time saving

- Reduced environmental impact

Automated Conveyor Cleaning

Automated Conveyor Cleaning