|

|

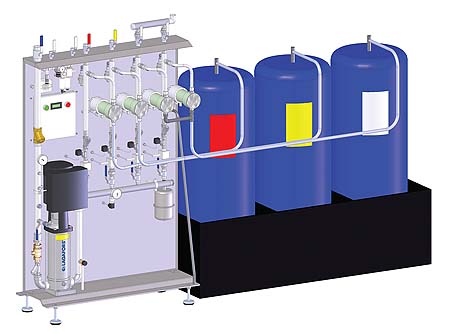

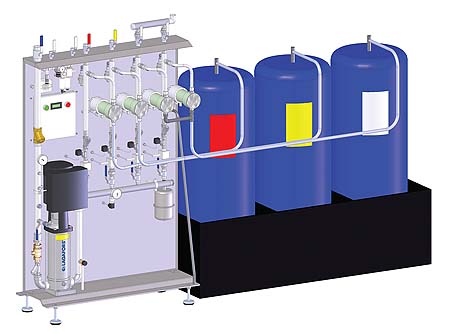

Variable Chemical Centre VCC II / 70

DESCRIPTION & FUNCTION

Lagafors'® unique, centralized chemical dosing system

VCC, Variable Chemical Centre, has now a newly developed successor - the

VCC II. In our development efforts, we have focused on increased

capacity and flexibility, improved materials and components, as well as

enhanced personal safety. Other features are much more efficient

maintenance and technical service. This unit is comprised of a pressure

pump, 1-4 chemical dosing modules and a controller. A dosing precision

of +/- 0,1% of the chemical solutions provides optimal chemical

concentration with maximal results. The unit can dose up to 4

simultaneous chemical solutions. Through the years, the VCC has been

shown to be especially suitable for environments with high demands on

hygiene and resource consumption, such as slaughterhouses, dairies,

breweries, the fish and meat processing industries and large-scale

kitchens.

- Main components: pressure booster pump, 1-4 chemical dosing modules and a controller.

- High dosing accuracy (+/- 0,1%), which guarantees low chemical consumption.

- Capacity of 1-12 simultaneous users (6-70 lit/min).

- Flexible, can handle various combinations of up to four chemical solutions.

- Level indicator with alarm is standard.

Features

- High dosage accuracy (+/- 0,1%)

- Constant chemical concentration

- Central storage of chemicals

- Central dosage

- Separate water systems

Benefits

- Reduced environmental impact

- No concentration fluctuation

- No concentrated chemicals in production area, less handling of chemicals

- Purchase of chemicals in containers

- Possibility to set desired temperature of diluted chemical solution

Facts

- Lower chemical cost

- Reduced chemical consumption

- Reduced risk of accidents with chemicals, no waste problems in chem tanks

- Reduced cost per liter of detergent, saving time when changing

- Optimal chemical efficiency, improved working environment, reduced amount of aerosol

-

TECHNICAL INFORMATION

Technical information Lagafors® Variable Chemical Centre VCC II

|

Model

|

70 S

|

70 D/SS

|

70 D/D

|

70 T/SSS

|

70 T/DS

|

70 Q/SSSS

|

70 Q/DSS

|

Dosing pumps

|

1

|

2

|

2

|

3

|

3

|

4

|

4

|

Outgoing water pressure

|

8 bar

|

Water consumption

|

0-35 lit/min

|

0-70 lit/min

|

Capacity (6 lit/user)

|

1-6 users

|

1-12* users

|

Surrounding temperature

|

5-30 ºC |

Connections incoming media (Internal thread)

|

Water incoming

|

ISO-G 1"

|

Water supply, flow

|

90 lit/min

|

Water supply, pressure

|

3-6 bar

|

Water temperature, max

|

30 ºC

|

Air (6-8 bar)

|

ISO-G 3/8"

|

Connections outgoing media (Internal thread)

|

Chemical solution to satellite

|

ISO-G 1/2"

|

2 x ISO-G 1/2" |

1 x ISO-G 1"

|

3 x ISO-G 1/2"

|

1 x ISO-G 1"

1 x ISO-G 1/2"

|

4 x ISO-G 1/2"

|

1 x ISO-G 1"

2 x ISO-G 1/2"

|

Air to satellite

|

ISO-G 3/8"

|

Electricity

|

Voltage

|

3 x 400 V + N + PE / 50 HZ

(other specifications on request)

|

Current

|

3,3 - 2,7 A

|

Power

|

1,5 kW

|

Dimensions

|

Measurements (W x H x D) - excl. cabinet

|

1150 x 1910 x 450 mm

|

Weight, approx.

|

135 kg

|

145 kg

|

145 kg

|

155 kg

|

155 kg

|

165 kg

|

165 kg

|

The data is subject to variation and the producer reserves the right to change design specifications without notice.

- Suction lance requires min. 52 mm hole in the chemical drum / container. - Protective cover not included and available separately.

* Maximum capacity due to the achieved maximum flow of water.

|

|

The food industry and particularly the meat industry is one of the most demanding industrial environments in terms of hygiene and safety at work. All surfaces and equipment must be of non-toxic, easy to clean and chemically and mechanically resistant ...More

We would kindly like to invite you to visit us in Hall 5.2., stand C041. ...more

We would kindly like to invite you to visit us in Hall C2, Stand 23-24. ...more

|

|