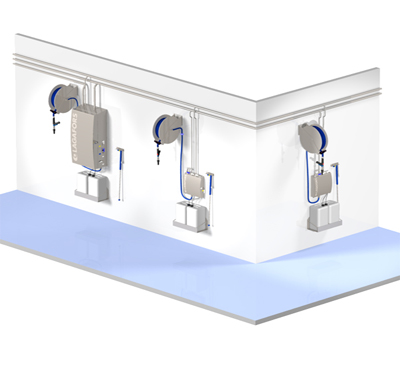

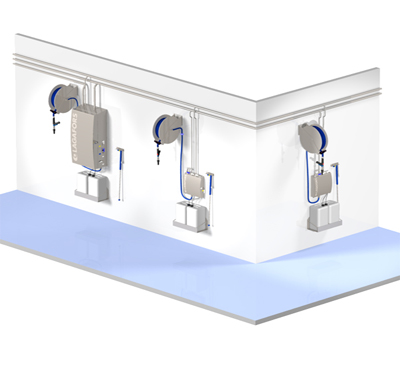

Decentralized systems

DESCRIPTION & FUNCTION

The new Lagafors® Decentralized Cleaning

System, DCS, helps companies in the food industry achieve first-class hygiene while at the same time delivering flexibility in the cleaning process. The DCS cleaning system is comprised of four main components that together comply with the highest capacity, performance and quality standards.

The main components supply the right pressure, flow and solution concentration to the places where they are needed. When used together with the Triggless® II spray gun, these components provide excellent ergonomic advantages.

Normally, the water pump unit is placed in a centrally located room. From this room, pipes are run to satellite stations located in the production area. Each satellite station is comprised of a hose reel with hoses for water, chemical solution and disinfectant solution. The Triggless® II spray gun and the PCN pre-cleaning nozzle are located by the hose.

The Lagafors DCS is suitable for installations of all sizes, but when using larger systems (>5 satellites), you should also consider installing a Lagafors CCS, Central Cleaning System.

Features

- Water pump unit

- VMS-DC satellite station

- Injector dosaging

- Triggless® II

- Pre-Cleaning Nozzle, PCN

Benefits

- Flexible pressure and flow

- Hygienic design

- Flexible

- Ergonomic, flexible and efficient spray gun

- User-adjusted pressure and flow

Facts

- Desired pressure and flow for up to five simultaneous users

- User friendly

- Easy to switch chemical

- No trigger, 0-150 bar, reduced muscle strain

- Efficient cleaning 0.3-7 m, with optimal water-consumption

THE FOUR MAIN COMPONENTS

Water pump units (LWP 20/40 CB)

The water pump centre is an essential component of the cleaning system. Lagafors offers a wide variety of pumps and customers can choose between different pressures (20-40 bar) as well as flow capacities for various numbers (1-5) of simultaneous users.

Variable media Satellite (VMS-DC)

The newly developed Variable Media Satellite (VMS-DC), decentralized, is a hygienically designed satellite station made in stainless steel for water rinsing, foam application and disinfection. The VMS-DC is wall mounted in production areas/ kitchens and suitable for water pressures between 5-160 bar. The satellite station has suction hoses with distinctive markings for chemicals and disinfectant. With an easy grip the operator changes between the different medias. Portable containers with chemicals concentrate are placed near the satellite station. Compressed air is connected to the VMS-DC unit. For capacity increase, the VMS-DCT offers distribution of up to three different chemicals (e.g. alkaline chemicals, acid chemicals and disinfectant).

Spray Gun (Triggless® II)

The

patented Triggless® II spray gun is ergonomically designed to reduce

muscle strain on the operator. The gun uses the reaction-force of the

water to keep the valve open instead of a traditional trigger. It is

light weight, safe whilst used with one hand and suitable for all

pressure levels up to 200 bars. During operation the Triggless® II can

be held in different ways to improve flexibility and efficiency. It

also features a “dead man’s” grip, i.e. the water flow is shut off if

the gun is accidentally dropped.

Pre-Cleaning Nozzle (PCN)

The

patent pending Pre-Cleaning Nozzle (PCN) enables the user to control

the water pressure for long or short distance cleaning, i.e. 0.3–7

metres. The purpose is to use the PCN instead of a high flow water-hose

in the pre-cleaning stage. Correctly used, this method can dramatically

reduce the water consumption. The weight of the Pre-Cleaning Nozzle is

only 125 grams.

Decentralized Cleaning System (351 KB)

Decentralized Cleaning System (351 KB)

Decentralized Cleaning System

Decentralized Cleaning System