|

|

|

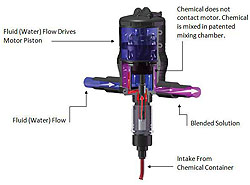

Dosing Units

Proven Chemical Injection Technology for Global Market ApplicationNovamix patented line of non-electric, fluid-driven proportional injectors are used to ensure precise chemical injection directly into the water or fluid line under various flow rates, feed ratios and different ranges of pressure. These award-winning injectors are extremely durable, manufactured from engineered proprietary composite materials to withstand the rigors of the elements, as well as chemicals for injection.

Injectors

Widest range of Models, Flow Range and Injection Rations in the IndustryNovamix

offers injectors for a variety of industrial applications; whether that

means adding medication for livestock, cleaning or disinfecting fluid

lines, sanitizing water systems, vehicle washing, cost effective

fertilizing, or pest control for crops and plants. Novamix injectors are

adaptable and cost effective, while creating a long-lasting solution

for your needs. Novamix injectors offer a wide range of sizes,

flow rates and feed ratios and can operate as stand-alone units or

within an OEM's system. They are most durable and

environmentally-friendly products available, while also meeting your

installation, cost and chemical challenges - help you get the job done

every time. Aplications- Food processing treatments

where disinfecting and surface cleaning are needed, such as bottle line

cleaning, deodorizing seafood ice displays, ice making sanitation.

- Fire fighting and prevention applications, such as fire suppression foaming chemicals.

- Horticulture

treatments, such as dispensing fertilizers, pesticides, herbicides,

fungicides, acids, and disinfectants in high flow applications.

- Metal

processing and parts wash treatments by dispensing coolants, oils,

solvents, cutting fluids, soaps in high flow applications.

- Pest

control applications by providing the accurate dispensing of chemicals

with minimal waste, pesticides, misting systems, panel systems

termiticides, spray trucks and vector control.

- Odor misting control for landfills dumpsters and oils.

- Specialty

applications, such as asphalt treatment, bio decontamination, water jet

cleaning, concrete treatment, and timber treatment.

- Vehicle washing treatments, to accurately dispense soaps, polishes, drying agents, and triple foam.

- Water treatment applications that injects chemicals into residential and industrial water supplies.

- Injecting diesel additives and treatment for diesel fuel.

Key features to look for an injector- No extra cost for proprietary composite body-which exceeds PVDF for chemical compatibility and for mixing aggressive chemicals

- No extra cost for built-in on/off switch, which allows user to stop the injection-but not the system

- Separate internal mixing chamber prevents chemical contact with motor piston-for longer life and uniform mixing

- Highest standard operating pressure in the industry-minimizes pressure loss

- 3-Year Warranty-best in the industry

Operating principleInstalled

directly in the fluid supply line, the injector operates without

electricity, using fluid pressure as the power source. The fluid drives

the injector, which pulls the required percentage of concentrate

directly from the chemical solution container. Inside the Novamix,

patented mixing chamber the concentrate is mixed with the fluid, and the

fluid pressure forces the mixed solution downstream. The amount of

concentrate will be directly proportional to the volume of fluid

entering the injector, regardless of variations in flow or pressure.

|

|

The food industry and particularly the meat industry is one of the most demanding industrial environments in terms of hygiene and safety at work. All surfaces and equipment must be of non-toxic, easy to clean and chemically and mechanically resistant ...More

We would kindly like to invite you to visit us in Hall 5.2., stand C041. ...more

We would kindly like to invite you to visit us in Hall C2, Stand 23-24. ...more

|

|