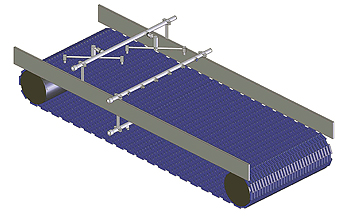

Stationary Flush Ramps SFR

DESCRIPTION & FUNCTION

The

Lagafors® stationary flush ramps, SFR, were developed for effective cleaning of conveyor belts and other conveyor systems in the food processing industry. Can be supplied with media from a satellite station using a regular hose or, which we recommend, using a pipe from a Lagafors® Automatic Cleaning System, ACS. The product series is divided into two main groups: Fixed and rotating ramps.

Rotating ramps for flushing increase the cleaning effectiveness and reduce water consumption. Fixed ramps can be used anywhere, but are especially suitable for tight spots (e.g. the inside of a conveyor belt). Fixed ramps can also be used to apply chemical and disinfectant foam solutions.

- Fixed positions for water as well as chemical and disinfectant solutions

- Rotating ramps for increased cleaning effectiveness and reduced water consumption

- Available in all sizes between 200 mm and 800 mm (larger sizes can also be supplied)

Features

- Fixed flushing

- Fixed flush ramp

- Rotating flush ramp

Benefits

- 100 % coverage

- Reduced work effort

- Space-efficient

- Increased cleaning effectiveness

Facts

- Maximize hygienic results

- Lower costs

- Suitable for tight spots

- Lower water consumption

Lagafors® Stationary Flush Ramps SFR

|

|

Fixed flush ramp, water

|

Rotating flush ramp, water

|

Fixed foam ramp

|

|

Connections

|

|

|

|

Supply media

|

1/2'' int. thread

|

1/2'' int. thread |

1/2'' int. thread |

|

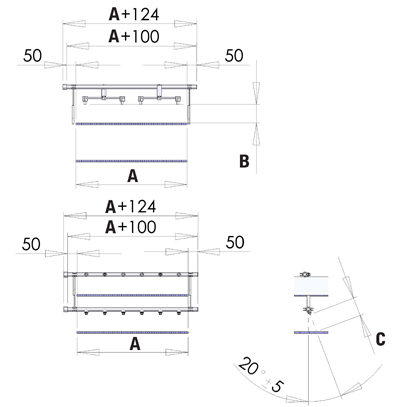

Dimensions

|

|

|

|

Pipes

|

21 mm

|

21 mm

|

21 mm

|

|

Angle of dispersal

|

|

|

|

| Nozzles/distance |

65º / C = 80-99 mm (recommended)

|

15º / B = 50-100 mm

|

40º **

|

| Nozzles/distance |

80º / C = 65-80 mm

|

|

|

Legend:

A = Belt width

B = Recommended flush distance for rotating flush ramp

C = Recommended flush distance for fixed flush ramp

* Pipe holders and nozzles not included. Must be ordered separately.

** During foam application, 20-25 % of the number of nozzles are used, e. g. one nozzle per 500 mm belt width. Foam application is carried out horizontally in the belt's direction of rotation.

The data is subject to variation and the producer reserves the right to change design specifications without notice.

Stationary Flush Ramps (382 KB)

Stationary Flush Ramps (382 KB)

Stationary Flush Ramps

Stationary Flush Ramps